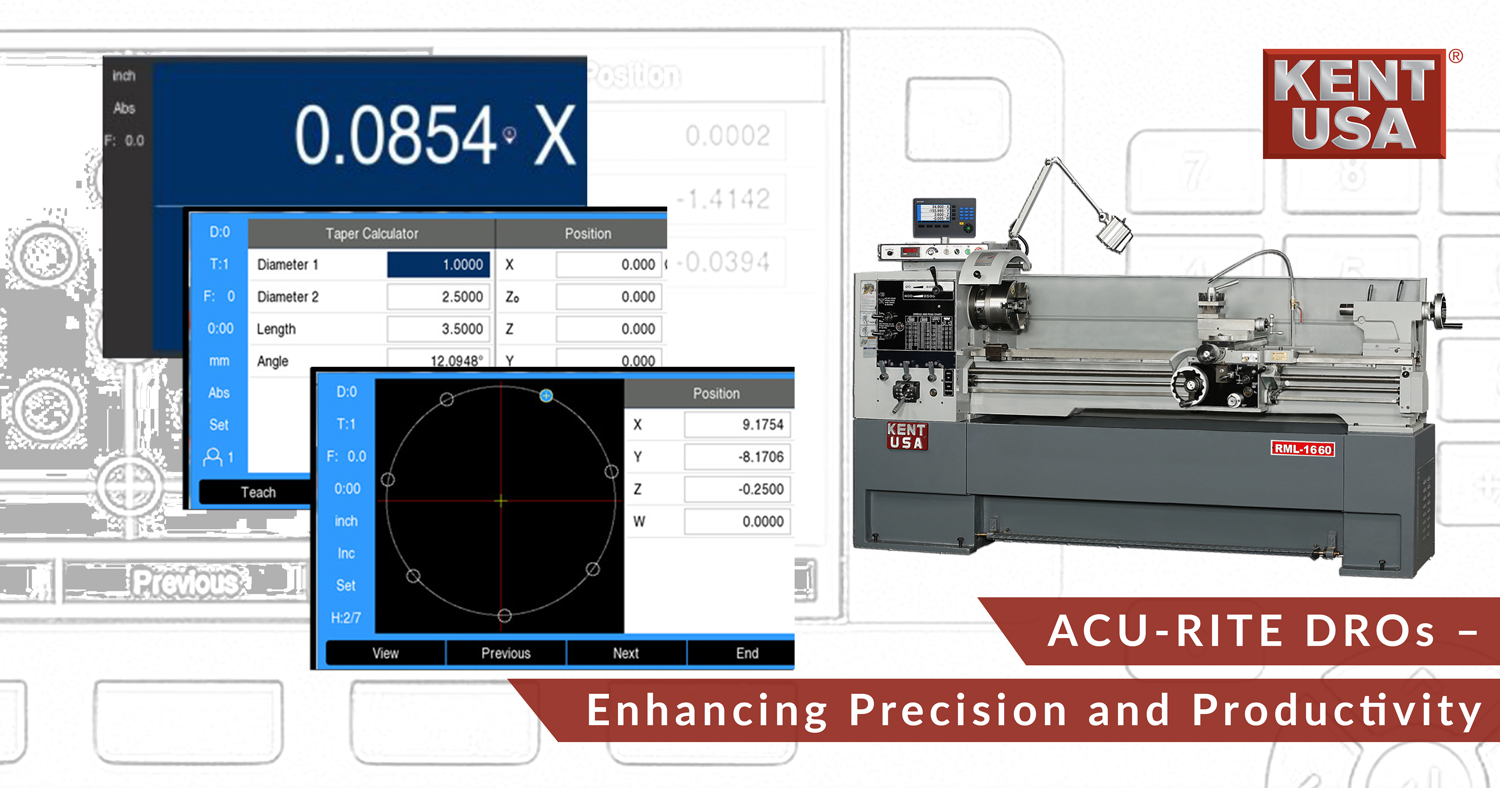

Digital Readout (DRO) systems have increasingly become more of a necessity than a luxury for many operators. They significantly enhance the accuracy, efficiency, and productivity of conventional machines, making them an essential addition to any machine shop. By providing precise digital measurements, DRO systems reduce manual measuring errors, improve quality control, and minimize operator fatigue. Through a decade-long partnership with Heidenhain, KENT USA® has fully integrated ACU-RITE DROs into its precision grinders, lathes, and milling machines. Most 2- to 3-axis machines are optionally equipped with the ACU-RITE DRO 203, which is especially well-suited for milling, drilling, boring, and lathe machines with up to three axes.

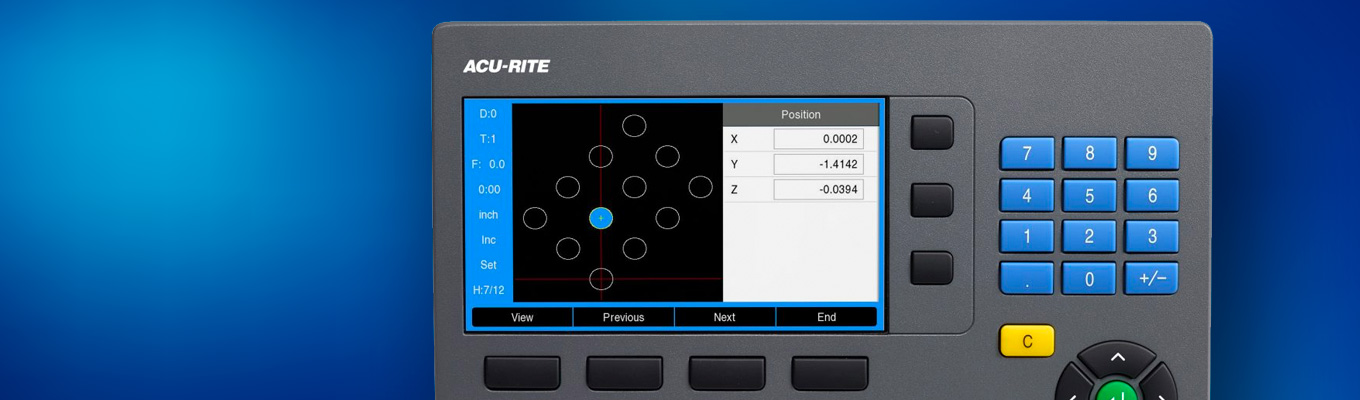

Design: The DRO 203 digital readout is built as a robust, upright unit with a splash-proof full-travel keypad, ideal for workshop use. It features a 7” TFT color screen that displays position values, dialog inputs, graphic functions, and a graphic positioning aid.

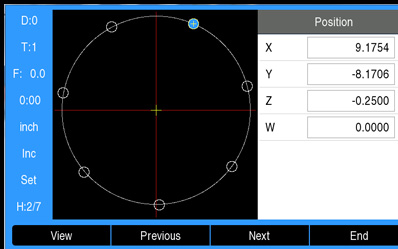

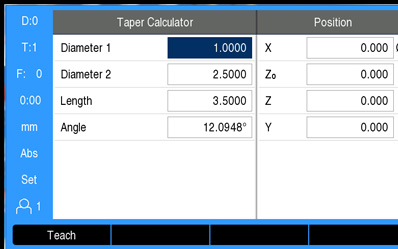

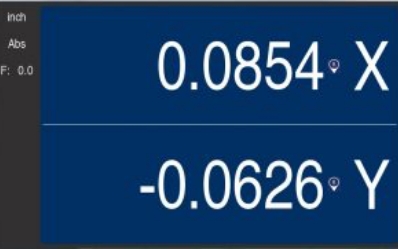

Milling, Drilling, Boring, and Turning Functions: The DRO 203 stands out with its Klartext dialog guidance, making it user-friendly. Its distance-to-go display simplifies positioning tasks; just traverse until the display reads zero to quickly and reliably reach the next position. For milling, drilling, and boring applications, the DRO 203 digital readout offers advanced features such as the calculation of positions for hole patterns, including bolt circles and linear hole patterns. It provides tool radius and tool length compensation to ensure precision and accuracy. Additionally, the DRO 203 supports both linear hole patterns and bolt-hole circles, making it a versatile tool for various machining tasks. For turning applications, the DRO 203 digital readout includes a taper calculator and the ability to switch between radius and diameter displays. It allows for freezing the tool position for back-off and offers vectoring, providing an X/Y display of the traverse path with an inclined top slide. Additionally, it features a sum display for Z and ZO, enabling axis coupling for enhanced precision and control.

Having an ACU-RITE DRO transforms KENT USA®’s manual machines into highly precise and efficient tools, ideal for both educational settings and professional manufacturing environments, ensuring consistent high-quality output and enhanced overall performance.

Features

Milling-specific features

|

Turning-specific features

|

Dynamic zoom The currently moving axis can be geographically highlighted. In “dynamic zoom” mode, the position value is zoomed to its maximum size depending on the number of digits. This greatly improves legibility—especially from a great distance. |

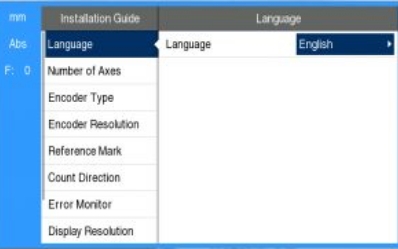

Installation guide When you switch on the digital readout for the first time, the DRO203 supports you with an installation guide. You are led step by step through the most important settings until the device is ready for operation. |

Day/night switching Depending on the ambient-light conditions at the machine, you can switch the screen of the DRO203 to a light or dark background. |