Buying a Lathe: What You Should Know Before Investing

Are you thinking about buying a lathe? One of the first things to determine is what you want to do with it and what kinds of materials you will cut. Are you a hobbyist looking to make some wooden candlestick holders and salad bowls? A benchtop wood lathe might be all you need. However, if you wish to hold greater accuracy or cut metals, a more rugged and versatile machine is in order. If you’re among the latter group of people or just want to know more about precision lathes in general, keep reading.

A Proud Legacy

Lathes are among the oldest of all metalworking machinery. In fact, many refer to them as the mother of machine tools for their ability to make parts for other machines. These include threaded fasteners, shafts, bushings, and much more, including the candlestick holders mentioned earlier. Historians will tell you it was the early Egyptians who invented the first crude lathes, yet it wasn’t until 1800 that they gained thread-cutting capabilities. That invention is attributed to Englishman Henry Maudslay, although others certainly laid the groundwork for his important work.

The Modern Lathe

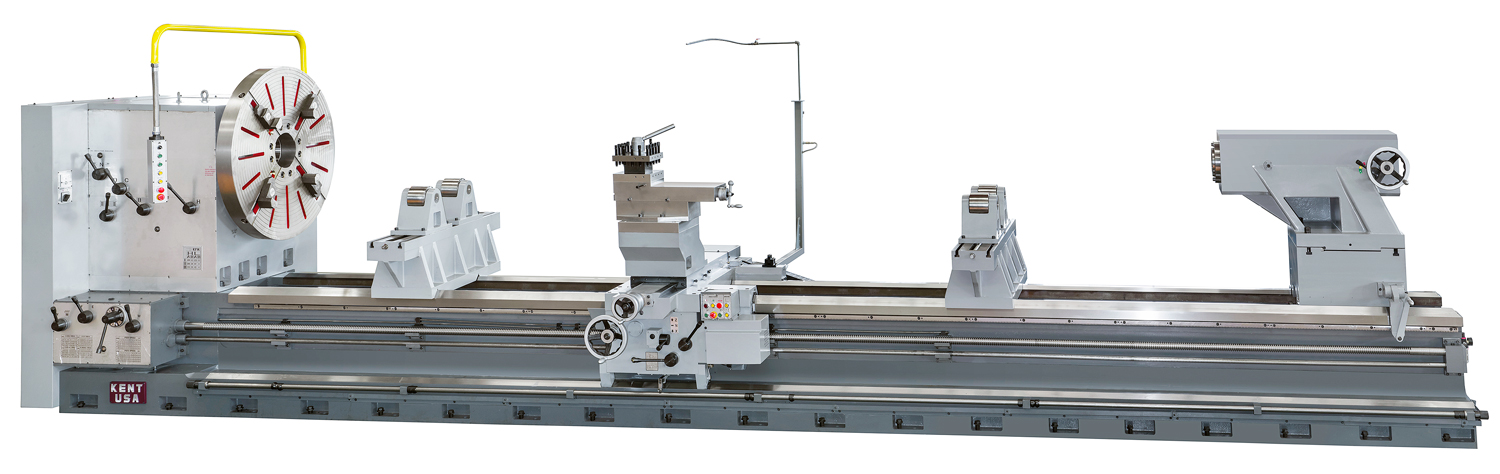

Henry Maudslay would recognize any of these modern metal-cutting lathes from Kent USA. All have hardened and groundway surfaces that allow the carriage to move longitudinally via a leadscrew. Sitting atop the carriage is a cross slide for axial motion, with a four-sided indexable tool post attached to that. A series of changeable gears power the carriage and give the lathe its screw-cutting capabilities, while a geared headstock provides plenty of power at the rotating spindle. For anyone interested in buying a lathe, these are just a few of the primary functions to keep in mind. The Kent USA MLX-2060T precision lathe is a very good example of a well-equipped modern lathe.

You Get What You Pay for

There’s way more to buying a lathe than these basics, however. Let’s start with the price tag. My father used to tell me, “You get what you pay for, son.” He wasn’t necessarily talking about machine tools, but his words remain valid nonetheless. Here’s the thing—if you want an inexpensive lathe, you won’t have to look too far to find one. There are plenty of entry-level machines listed on websites and in catalogs that seem to offer a good bang for the buck. And even though they might be similar in appearance and function as those listed on the Kent USA website, looks can be deceiving (another of my Dad’s many adages), and a year or two of use will prove differently.

“She’s So Heavy”

“She’s So Heavy”

John Lennon was writing about Yoko Ono in this classic Beatles’ tune, but he might just as well have been buying a lathe. Consider this: Kent USA’s TRL-1340 Lathe comes in at a hefty 2200 lbs. Compared to a benchtop or bargain brand lathe, it’s a big step up, and yet, it’s the lightest machine in the Kent USA lineup. Who cares? You should. A heavy machine means heavier cuts, greater rigidity, and less vibration. For the longest life and highest precision, always opt for a lathe with a heavy cast iron base, not one constructed made of welded steel.

The Headstock

The headstock and its rotating spindle is the heart of the lathe. It goes without saying that you should look at available horsepower—anything less than 2 HP or so will be inadequate for metal cutting. Also, make certain that the chuck is large enough to grip whatever workpieces you have in mind and that it has a standard Camlock-style or equivalent spindle mount. Beyond that, be sure to ask about the type of bearings used, how many, and how far apart they are. A cheap spindle with low-quality bearings will cause nothing but problems a year or two down the road.

Get in the Swing

Swing indicates the maximum diameter workpiece you can turn on a lathe. Measure from the top of the bed to the center of the spindle and then double that value. Similarly, the bed measurement is the maximum length of the workpiece that you can turn. It’s determined by the distance between the spindle face and tailstock. Also, look at the bed width. Wider ones provide greater stability and better results in turning operations. You should consider all of these factors before buying a lathe.

The Shopping List

What else separates the good from the not-so-good when buying a lathe? You’ll want a foot brake for stopping the spindle quickly. A geared headstock with multiple speed ranges helps to make sure you have plenty of available power. Hardened and ground ways assure years of productive use. A job button makes gear changes easier. Hobbyists probably won’t care about inch/metric dials, but someone starting a machine shop will. They’ll also care about cutting threads, so make certain your lathe has the right thread-cutting capabilities.

A Few Turning Accessories to Consider

The tool post should make it easy to change and adjust tools. For shaft work and other longish parts, you’ll probably need a steady rest. This is an attachment that bolts to the bed and supports the workpiece while turning. You’ll need a three-jaw and four-jaw chuck, as well as a faceplate, live center, and various Morse taper adapters for the tailstock. How about power? If your shop has 220-volt, three-phase electricity, so much the better. If not, be sure to pick up a phase converter or buy a lathe able to run on a 110-volt single phase. And if you have the cash, a digital readout (DRO) makes lathe operation much easier and less prone to mistakes.

Buying a Lathe: the Final Word

Granted, you’re facing a significant investment right now. Before whipping out your credit card, take a look at the big picture, and determine what will be best for you long term. Yes, a hobbyist or someone just getting started can often get by with a bargain brand machine. As their needs grow, however, this could end up being a mistake. Spending a bit more now on an industrial-quality lathe means better parts and far less hassle. That, and a larger, heavier, more rigid machine typically saves its owner money on repairs and replacement parts in the future. Whatever else you do, be sure to kick plenty of tires, and give us a call to discuss your project.

PS: You Might Want to Consider CNC Teach Lathes

CNC Precision Teach Lathes Series allows any shop to step up to CNC turning. It’s easy to learn teach-in conversational programming enables machinists of any skill level to produce higher quality parts with lower labor costs. These CNC lathes are perfect for machine shops transitioning to CNC and for machine tool technical schools. Read more about CNC Precision Lathes.