The pallet changer has long been associated with high volume work on horizontal machining centers (HMCs). However, that paradigm is beginning to shift. Automakers and prototype shops alike find that machines such as Kent CNC’s KMH Auto Pallet HMC enjoy OEE levels (overall equipment effectiveness) much higher than those who swap parts by hand. Four-sided machining is possible, and shops can also set up one job while another is running. Doing so increases flexibility, allowing companies to more easily meet changing customer demands.

Define Pallet Changer

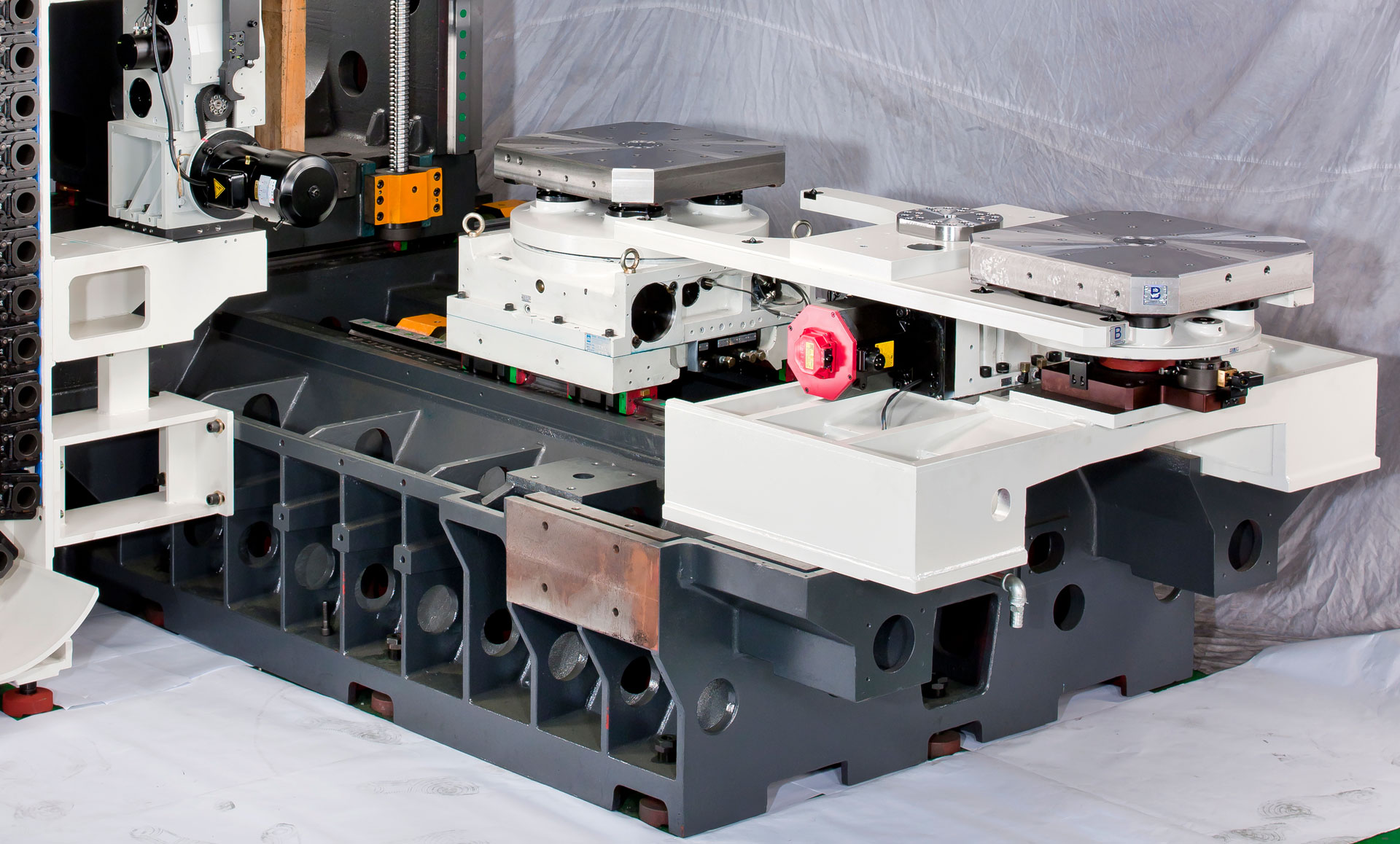

The term pallet changer is just as it sounds. A metal pallet carrying a vise, fixture, or tombstone moves into and out of the machining center, usually on a pair of rails. In most cases, the machine executes this function on its own. This might be based on an M-code or perhaps a signal from a cell controller. This is known as an APC, short for automatic pallet changer.

Changing on the Cheap

There’s more than one way the skin the palletized cat, though. For example, some machine tool accessory companies offer precision ground fixture plates that fit onto two or more pins. When the cycle’s complete, the operator pushes a button to release the pallet, then swaps it for another. Although manual, this approach is quite cost-effective and offers many of the same benefits as a dedicated pallet changer.

The Robotic Pallet Changer

Given the ongoing shortage of skilled workers, many shops are turning to robots. Here again, a pallet changer is a great way to meet the need for automation. By equipping pallets with an automatic air blast and clamping capabilities, the robot can easily swap jobs or parts, just like a human (but without breaks or vacations). Just be sure to check with your machine tool dealer that you have enough M-codes for the additional functions.

The Aftermarket Pallet Changer

Everything just described applies to VMCs and HMCs, or even those that straddle the fence. For shops with a vertical machining center (VMC), there are several aftermarket equipment manufacturers who provide such systems. Just Google “pallet changer” and you’ll find inexpensive manual or automatic devices that you or an integrator can install. Better yet, ask your machine tool salesperson for help. That’s what they do.

The Low-Down on Pallet Changers

Still letting your machine spindle sit idle while swapping parts? Take it offline. A pallet changer makes the most of your machine tool. For a few thousand bucks, greater OEE is there for the taking. So is increased flexibility. Spend a bit more for a robot-friendly version, or go all out and invest in a retrofit. The latter is nearly as capable as a dedicated pallet-changing HMC (well, almost). Whatever route you take, it’s time for a change.

Share this article: