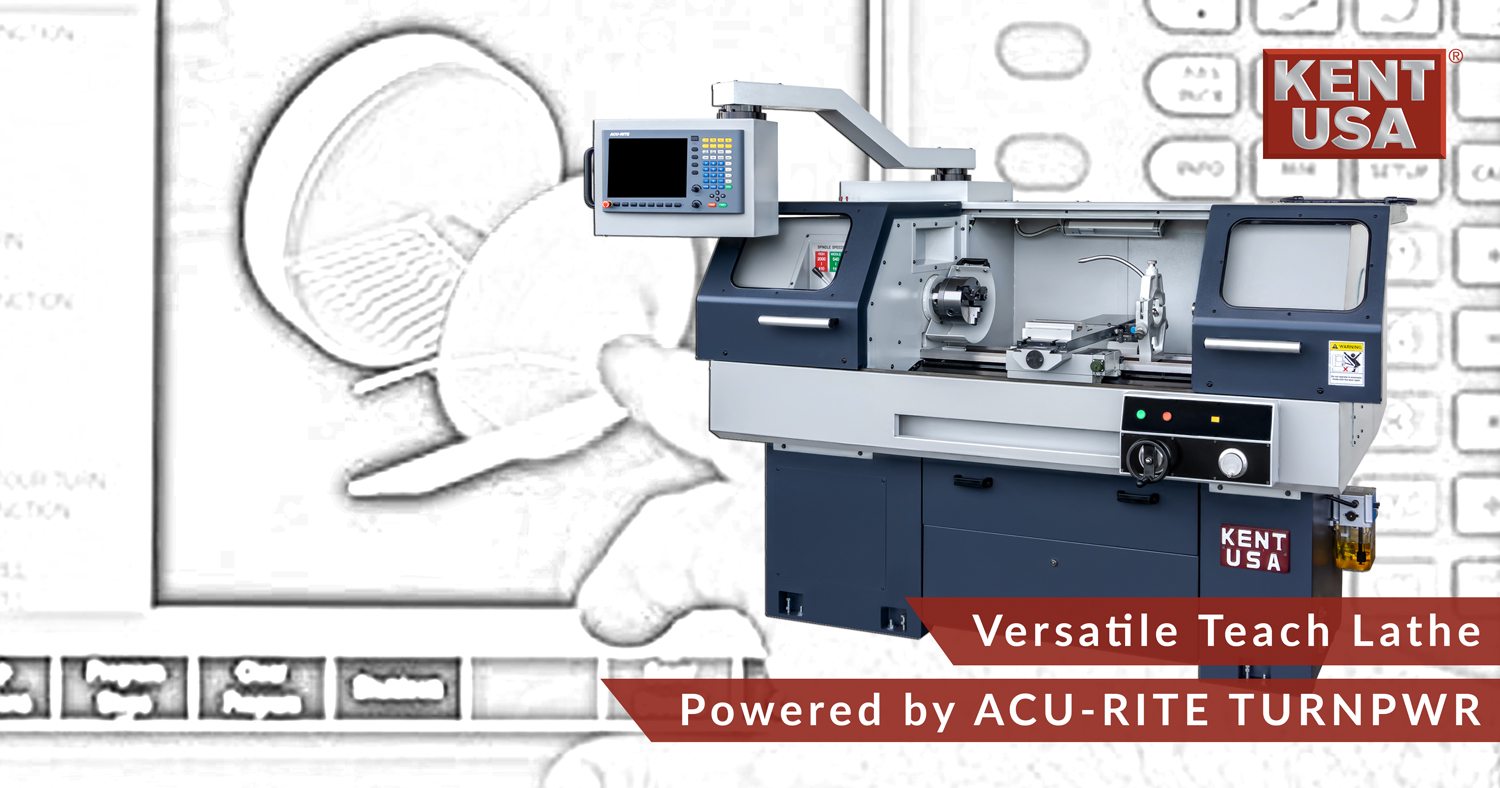

The KENT USA® CNC Precision Teach Lathes Series powered by the ACU-RITE TURNPWR allows any shop to step up to CNC turning. Its easy-to-learn teach-in conversational programming enables machinists of any skill level to produce higher-quality parts with lower labor costs. These CNC lathes are perfect for machine shops transitioning to CNC and for machine tool technical schools. KENT USA® CNC Precision Series Lathes come in work capacities of 14” x 40” to 22” x 120”, spindle bores of 1.5” to 3.582”, and up to 15 HP of spindle motor.

• Factory Installed w/ ACU-RITE TURNPWR Control

• 7.5 HP Peak Frequency Drive Spindle motor

• Manual and CNC mode conversational control

• Rigid Meehanite® castings with extra ribbing

• Induction hardened and ground ways

• Gearbox with alloy steel gears that are hardened and ground

• Extra large precision ground ballscrews

• 50-2,000 RPM range; MPG electronic handwheel

• Auto Lube system with metered Check valves

| Swing Over Bed: | 14″ / 16” |

| Swing Over Cross slide: | 7.48″ / 8.46” |

| Distance Between Centers: | 40” |

| Width of Bed: | 8.1″ / 11” |

| Spindle Nose: | Camlock D1-4 / D1-6 (Opt. ASA A1-6) |

| Spindle Bore: | 1.5″ / 2.25” |

| Spindle Taper: | MT #5 / #6 |

| Spindle Speeds: | 50-2000 RPM (2 ranges) |

| Longitudinal Travel (Z-Axis): | 33” |

| Cross Slide Travel (X-Axis): | 8” |

| Z-Axis Ballscrew Diameter: | 1.259”, 5 mm pitch |

| X-Axis Ballscrew Diameter: | 0.98”, 5 mm pitch |

| Z-Axis Rapid Traverse Speed: | 236”/min |

| X-Axis Rapid Traverse Speed: | 236”/min |

| Tailstock Quill Diameter: | 1.75″ / 2.12” |

| Tailstock Quill Travel: | 4.75″ / 5.1” |

| Tailstock Taper: | MT #4 |

| Spindle Motor: | 5 HP / 7.5 HP |

| AC Servo Motor (Z-Axis): | 1.1 HP / 1.2 HP |

| AC Servo Motor (X-Axis): | 1.1 HP / 1.7 HP |

| Net Weight: | 2530 LBS / 3520 LBS |

| Gross Weight: | 2750 LBS / 3740 LBS |

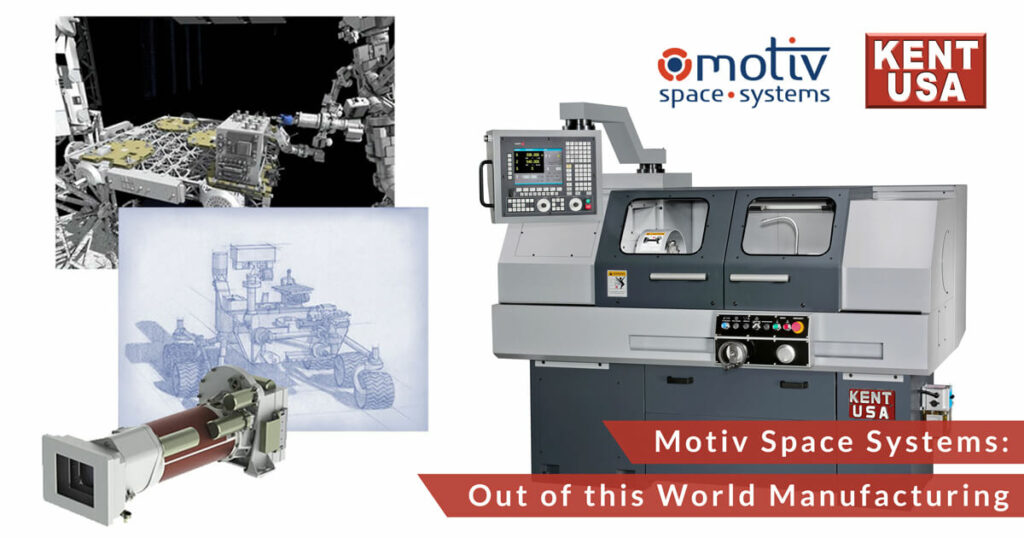

CSM-1440 Teach Lathe in Mars Rover Production

Scott Vanderzyl, Principal Manufacturing Engineer at Motiv Space Systems, purchased four of our machines and has this to say:

“We have a unique and broad combination of capabilities and offerings across the entire motion control and robotics arenas but packaged in a small business environment. This allows us to stay very nimble while still providing highly critical customized solutions for extremely challenging applications. We make tube sections for the robotic arm for the Mars Mission on our Kent USA CNC CSM-1440 lathe as well as custom match machining for all of the actuators and mechanisms.” Read More

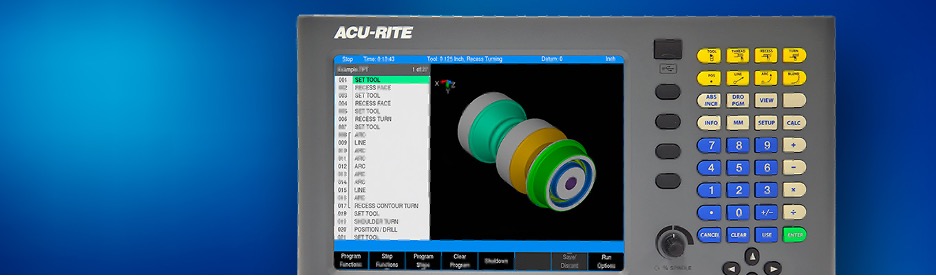

The TURNPWR Lathe Control

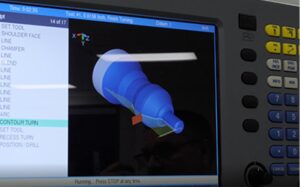

TURNPWR is a workshop-oriented turning control that enables the user to program conventional machining operations right at the machine. It is designed for turning machine tools with up to two axes. TURNPWR was developed to satisfy the wants and needs of lathe machinists where manual and automated operation are both useful and needed. TURNPWR promises to enable the user to maximize throughput by significantly reducing setup time, scrap and other non-productive operations.

Conversational programming

The well-known ACU-RITE conversational programming format for controls is a user-friendly method of writing part programs and included in the TURNPWR, however G-code (ISO) programming can also be used. Basic editing of G-code programs is also possible.

Large high-resolution display

A 12.1″ high-resolution display boasts a screen layout that is clearly arranged and user friendly. You can preview graphics in the editor and illustrate individual machining steps and corresponding tool path when programming contours, using only dimensions pulled from a production drawing. DXF files are also compatible.

Position-Trac™

TURNPWR is a closed-loop system with positioning feedback provided by rotary encoders inside the motor assemblies. When fitted with the (optional) ACU-RITE precision glass scales (1 µm/0.00005″ resolution), TURNPWR also includes Position-Trac™, an advanced feature that enables the user to easily, quickly and accurately re-establish work piece zero after shutting down or power loss.

SPECIFICATIONS

| DRO Mode | • Multiple Datums (Fixture Offset): 99 • Zero Reset • Near Zero Warning |

|

| PGM Mode | • Thread Cycles, Recess Cycles, Turning Cycles • Position / Drill, LINE, ARC, BLEND (Blend / Chamfer) • Estimated Machining Time • View Graphics: 2D Line / 3D Line / 3D Solid • Block Form w/ User Override • Replication (Repeat) • Comment Step – Event comments • Program Manager Navigation Tree w/ Program Type Filter • Long Program Names • Program Preview: Listing & Graphic w/ Estimated Machining Time • Explode Step: Repeat |

• Reverse (Step / Path) • Shift Steps • Auto Save (Program) • Program Size Limit (TPT only): 9999 Steps • DXF File Import • G-code Program: w/Graphics Support / Simple Edit • On-Screen Help: User Manual Viewer (Text & Graphics) • Parts Counter & Clock • Optional Stop (G-code Only) • Feed Override: Potentiometer • Error Compensation: Linear & Bidirectional Non-linear |

| Processor | 1.4 GHz Dual Core Celeron® Processor | |

| Display | 12.1-inch 1024 x 768 Color LED | |

| Internal Storage | 2.5 GB CFAST (SATA) User | |

| Remote Handwheel | Standard with AC kits | |

| Housing | Die Cast Metal Bezel & Enclosure (Back Sheet Metal, Kit Style Console) | |

| Connections | Ethernet, USB (x2) | |

| Accessories | • Linear Feedback • Electronic Edgefinder • Offline Software |

|

| Weight | ~7.7 kg | |

| Electrical Requirements | AC 100 V to 240 V (±10 %), 50 Hz to 60 Hz (±2 %) | |

| Operating Temperature | 0° to 45º C (32º to 113º F) | |

| Storage Temperature | -20º to 70º C (-4º to 158º F) | |

| Protection | IP 54 (Front) / IP 40 (Back) (Kit Style Console) | |