There are several tried-and-true secrets for running a successful machine shop. For the Production Lead, the Machining Technology Program Instructor and the hobbyist alike, one of the simplest places to start: buy your new equipment in duplicate. It’s a worthy investment, many journeymen will attest. The reasons? Let’s consider:

1. Prevent Single Point of Failure (SPOF) Delays

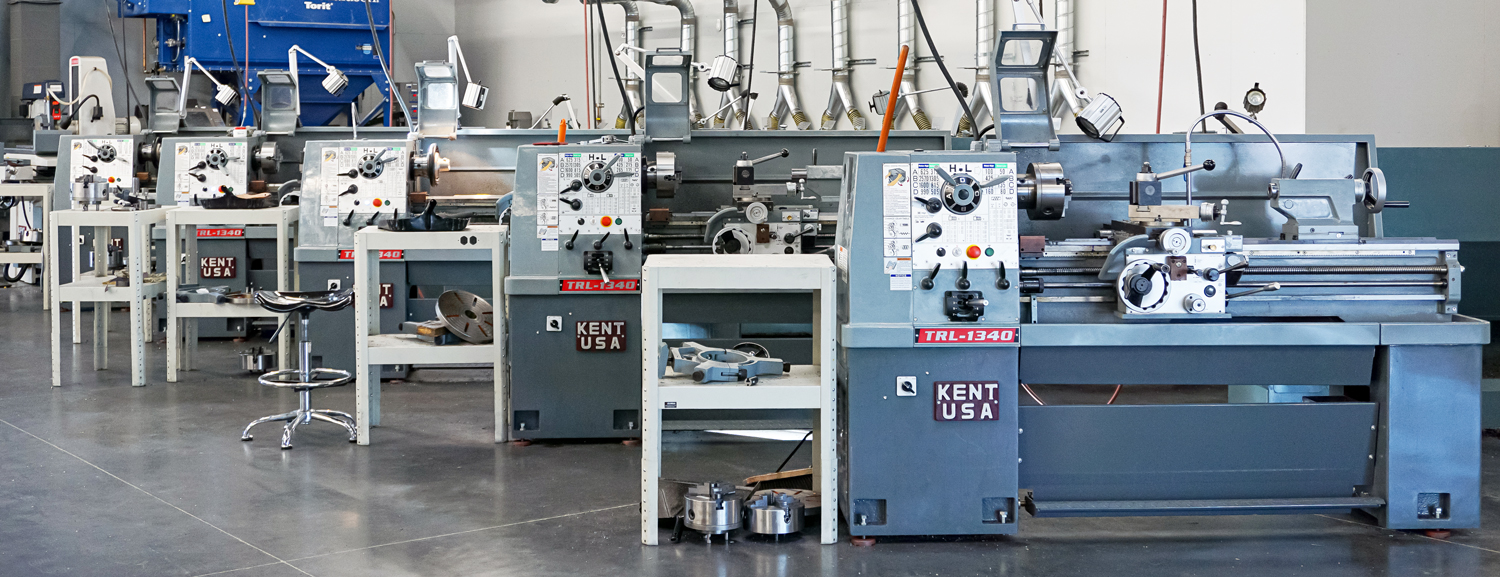

Your new KENT USA® TRL-1340 precision lathe may be a robust piece of equipment—with hardened and ground bedways to boot—yet components will inevitably wear-out or break from time to time. Some problems can temporarily halt use of the entire machine. This is when your second machine will come in clutch, picking up the slack so that production continues and / or your students can continue their pursuits of precision without interruption. Lead times are met, customers are happy and machining students complete the necessary curriculum on schedule.

2. Maintenance Becomes an Easier Task

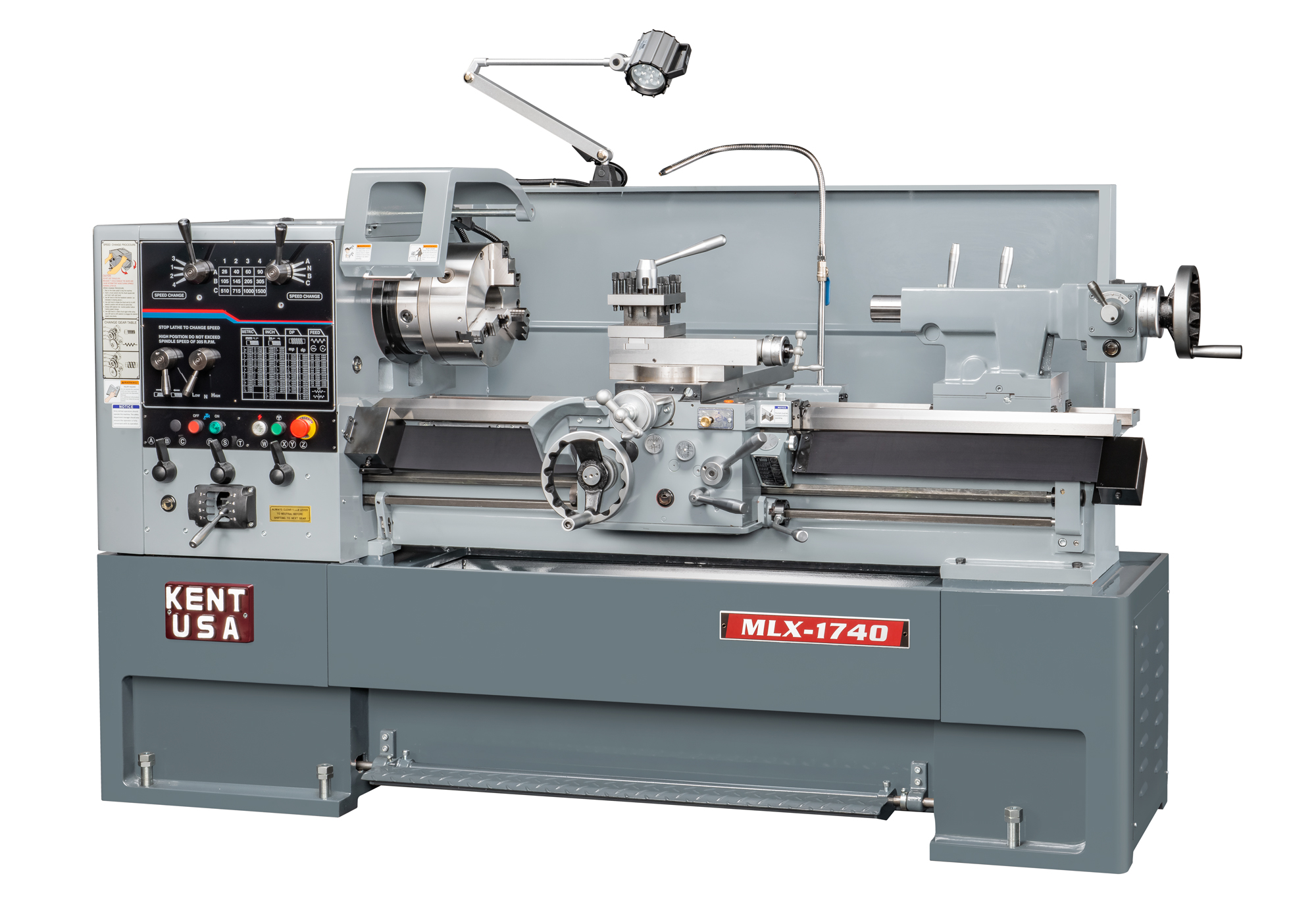

With only one KENT USA® ML-1740T lathe, performing the necessary routine maintenance and repairs will impact production time. Two machines help keep headaches to a minimum: you can take one machine offline for servicing while the other machine carries the day. No need to explain to your customer that the unexpected delay is due to a lone machine awaiting service. Your second machine carried the load. Operations move forward per normal with customer faith intact, problem solved ahead of time.

3. Training is Simplified

Many prosperous machine shops adopt a practice of keeping one machine for training, with the other for production runs. Apprentices need not worry that broken tooling as a result of inexperience—or worse, a broken spindle—will bog down the boss’s operation. Production runs continue no matter the comedy of errors visited upon the still-green machinist.

4. No Need to Swap Chucks, Collet Systems, Etc.

This may be a favorite reason among seasoned technicians and engineers to buy in duplicate: go ahead and keep a 4-jaw chuck on one lathe, with a 3-jaw chuck on the other. Or keep a collet set-up on one lathe, with a larger chuck on the other. No time wasted endlessly swapping these out. One lathe is for the quick-and-dirty work, the other for the jobs requiring more precision. Alternating between the two machines saves lost production that occurs when time is devoted to a different set-up. Machine floor operations continue with confidence.

5. Your Lathes Will Last Longer

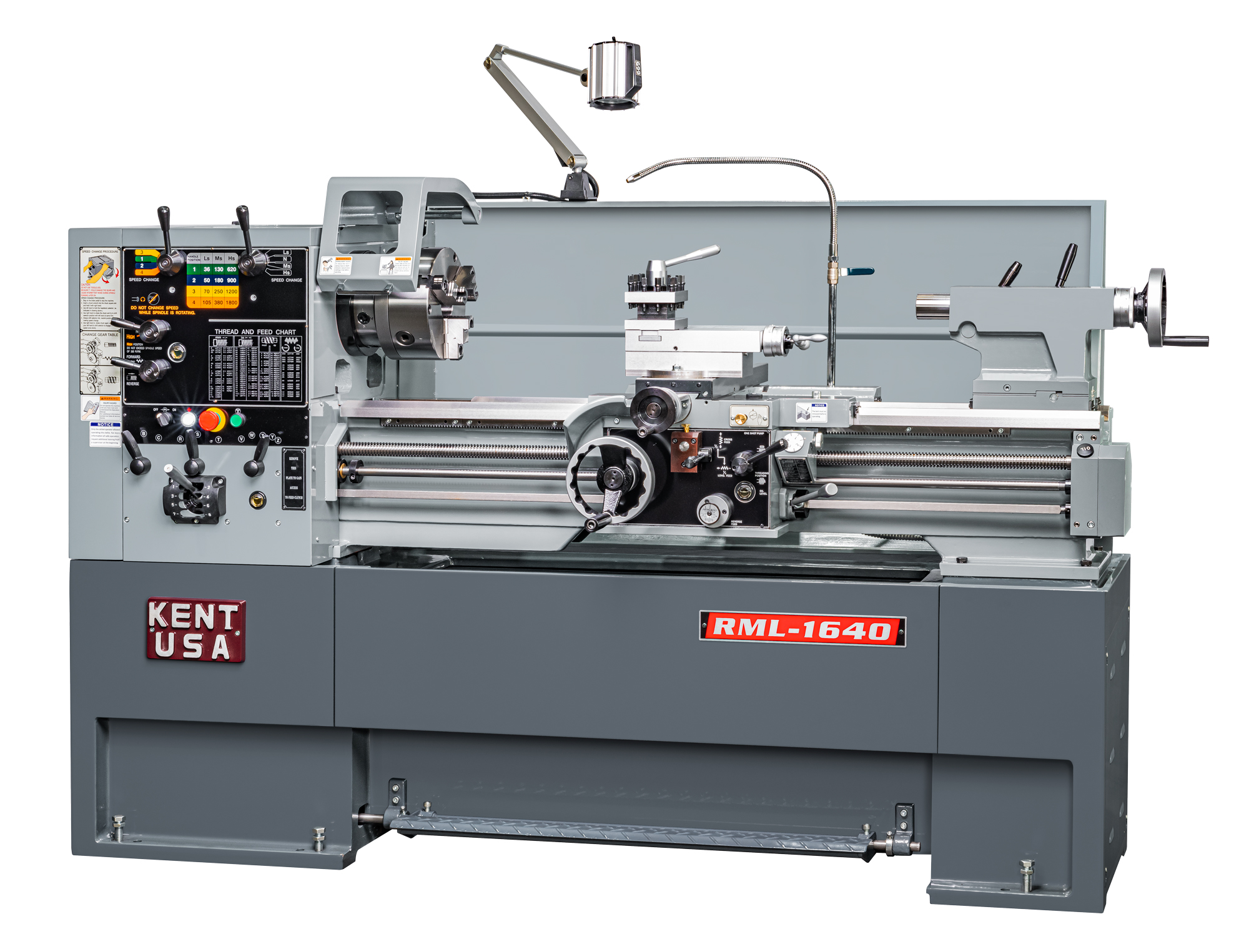

Owning two identical KENT USA® RML-1640 lathes ensures that one will periodically pick up the slack for the other, allowing for less taxing use and abuse of your machines over time. With proper care, your machines are better preserved for longer-term use. The knowledge you acquire over time for one machine, you will be able to apply intuitively to the other—removing all needless guesswork. You’ll find that your two lathes work in tandem as part of your overall operation, holding up better in the long run.

Experienced machinists of all levels from job shops large and small agree: buying your new KENT USA® lathe in duplicate pays dividends and saves headaches for all. It’s like having one machine, but twice as good. But then, that’s only half as good as having four. . .

Written by:

Marlene Flynn

Strategic Account Specialist, Sales