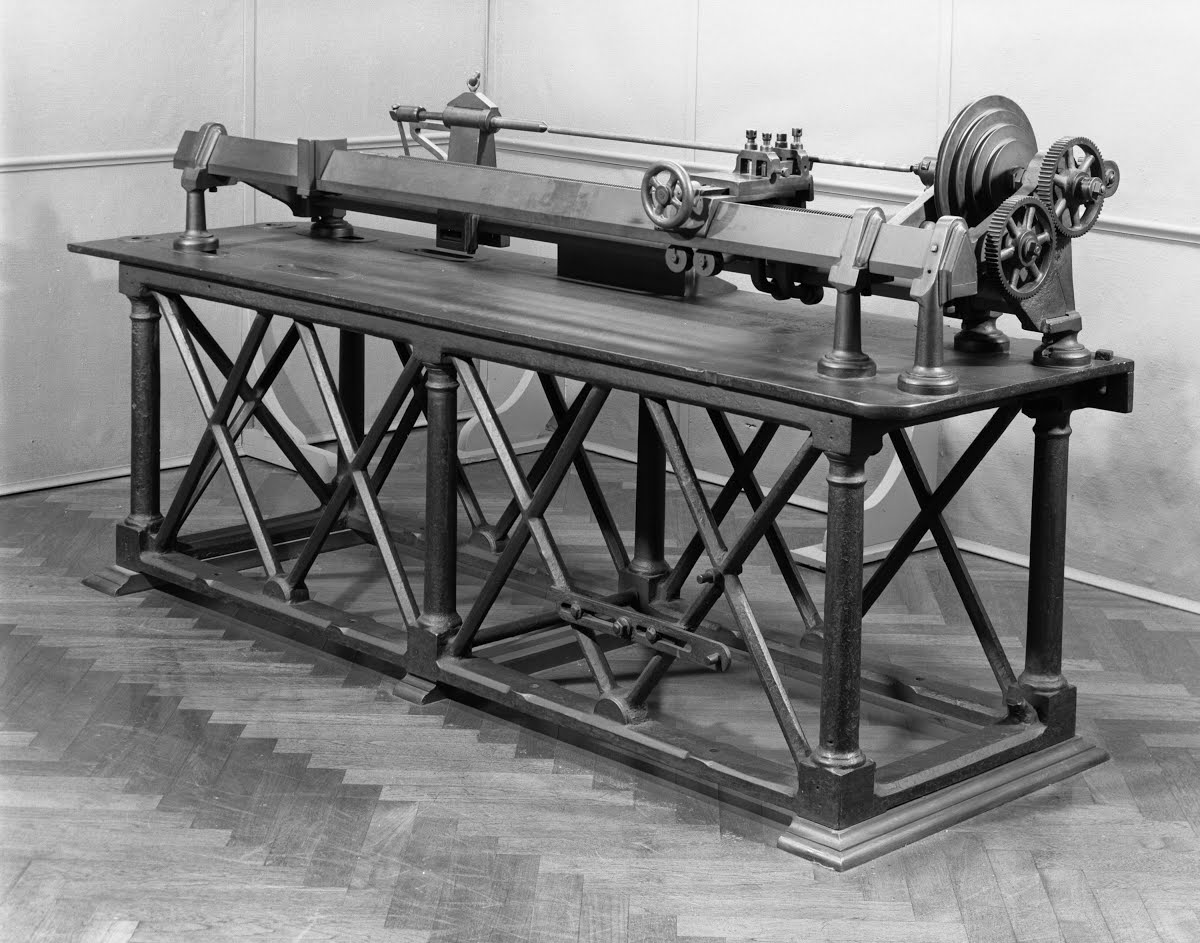

Anyone surfing the internet on the search term “metalworking lathes for sale” should take a moment to recognize British engineer Henry Maudslay. After all, he invented the first screw-cutting lathe more than two centuries ago. It wasn’t the first such machine tool, mind you. Lathes have been around since Egyptian times, and Maudslay certainly built on the work of others before him. Yet his invention did much to speed the First Industrial Revolution. Without it, there would have been no way to accurately machine the interchangeable threaded parts so critical to modern industry. Thanks, Henry!

Manual Metalworking Lathes for Sale

If you’re looking to make some of those threaded parts, you’re in luck. There’s no shortage of manual and CNC lathes able to efficiently cut screws, nuts, bolts, and much more. Even better, they can do so far more quickly and accurately than Maudslay would have dreamt possible.

Consider this MLX-2060T engine lathe from KENT USA®. With its geared head and adjustable leadscrew mechanism, machinists can easily turn out parts with 2 to 72 threads per inch (TPI) or 0.2 to 14 pitch in metric. Of course, they can also tackle a wide range of other turning tasks such as drilling, boring, grooving, etc.

So can toolroom lathes like the CTL-618EVS, albeit on a smaller scale. Utilizing a flatbed construction and 4000-rpm, infinitely variable spindle, these turning machines are a favorite of tool and die makers, prototype shops, hobbyists, and those looking for a general-purpose machine offering speed, flexibility, and extreme precision.

Automatic Metalworking Lathes for Sale

The next style of turning machine is the teach lathe, sometimes called a combo- or half-CNC. As the name suggests, they can be operated in manual mode, full auto, or a combination of the two. This makes them a great option for trade schools and shops new to CNC. They’re also a big help for shops that occasionally make complex parts and higher production volumes. Just set up the first one and let ‘er rip.

Of course, where would the modern machining world be without CNC lathes? No handles here, just power, speed, and productivity. For simpler parts, two-axis lathes like the KLR-Series or KLT-Series can tackle anything you might throw at the machines listed earlier. If those parts have milled slots or cross holes, though, a mill-turn center from Kent’s KLM family of multitasking lathes can save you a trip to the milling department.

There’s plenty more. Big bore lathes, sometimes called Oil Country lathes, are a common sight in shops making oil and gas components.

Gang-style CNC lathes are popular with anyone making small parts in large volumes,

while Vertical Turret Lathes (VTLs) are widely used to make automotive parts like bearing housings and gear blanks. Altogether, Kent USA and Kent CNC offer more than 50 models of manual, teach, and CNC lathe, each designed to meet your unique requirements for many years to come. Give us a call or fire off an email if you’d like to hear more.

Share this article: